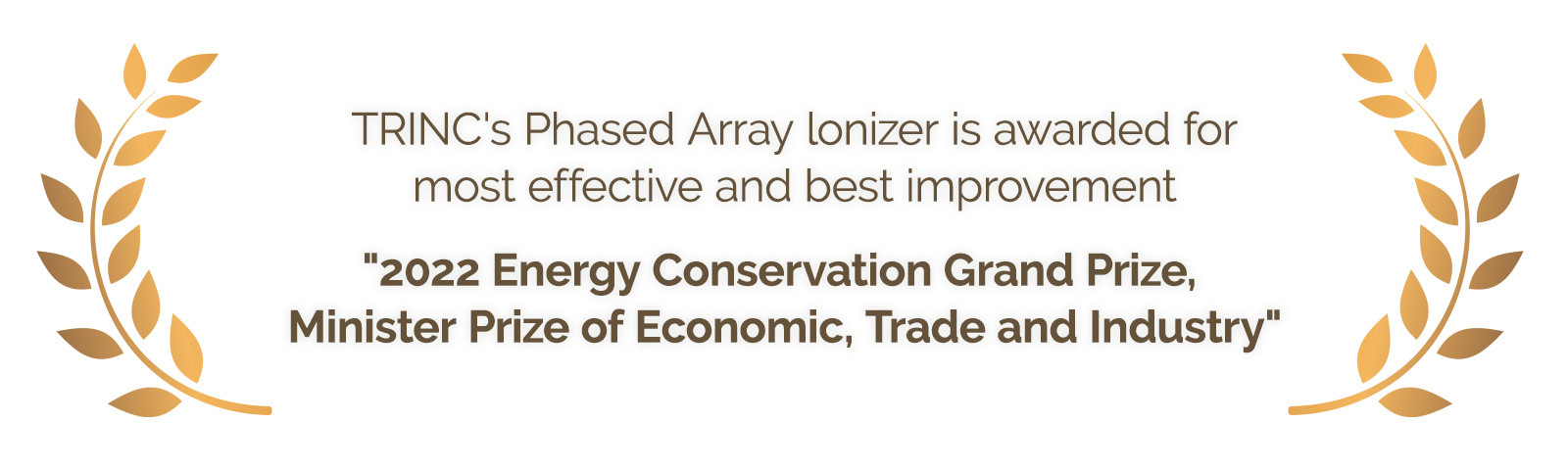

“Phazed Array Ionizer® = ESG’s effective means”

are demonstrated

Examples of Toyota Industries Corporation, Anjo Plant Improvements

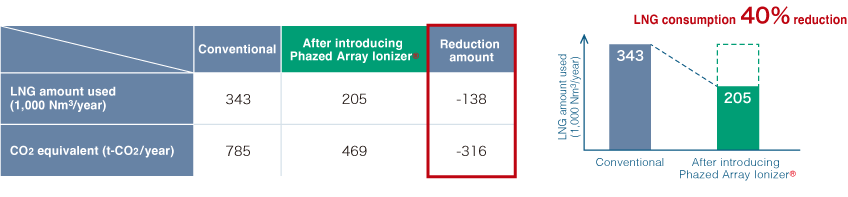

Problem before introduction

The entire factory was air-conditioned for product quality control, but in the winter when the humidity drops, a large amount of steam was required to humidify the factory, resulting in an increase in the consumption of LNG (liquefied natural gas).

Measures content

Installation of Phased Array Ionizer®

The devices were installed in areas intensively where static electricity countermeasures were especially important.

Achievement

- A higher level of static electricity countermeasures came to be possible

- Relaxation of humidity control level

- Reduction of plant LNG (liquefied natural gas): 40%

Key points for Ionizer selection

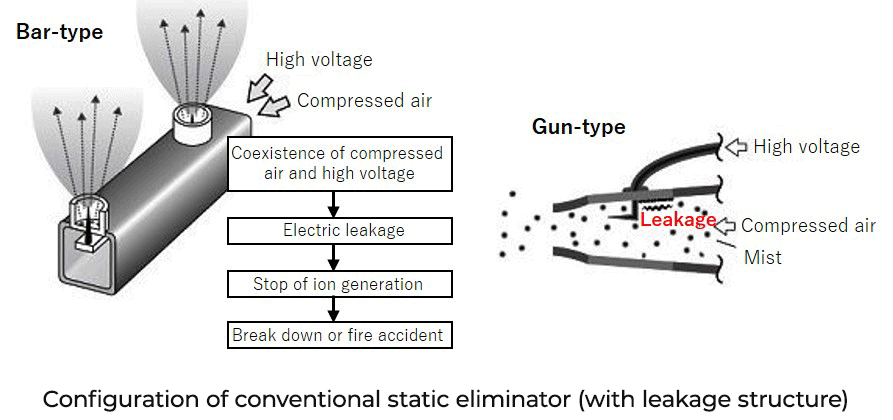

Is the Ionizer free from breaking down?

Static eliminators that have a poor design carry the risk of electrical leaks, which can ignite fires in the workplace. Therefore, it is advisable to avoid using static eliminators that rely on compressed air and high voltage for long-term purposes in the workplace.

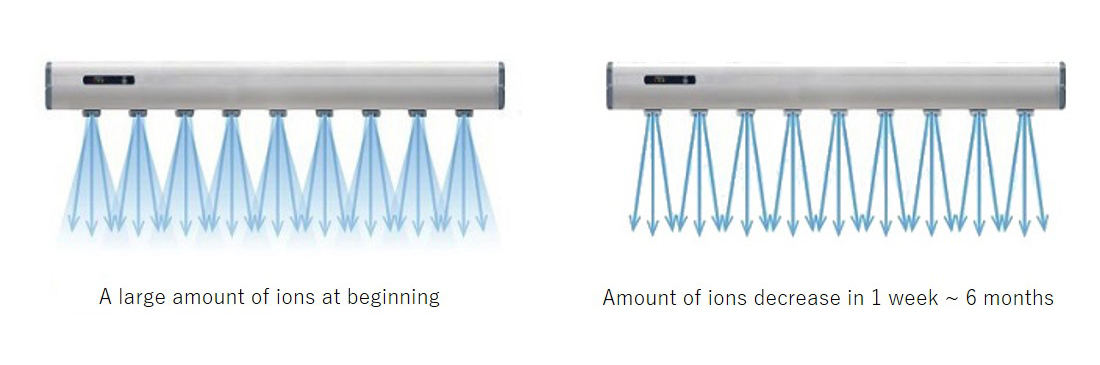

Does the Ionizer work powerfully and stably?

The ionizing ability of certain static eliminators weakens quickly over time. Additionally, when an electrical leak occurs, the quantity of generated ions gradually decreases.

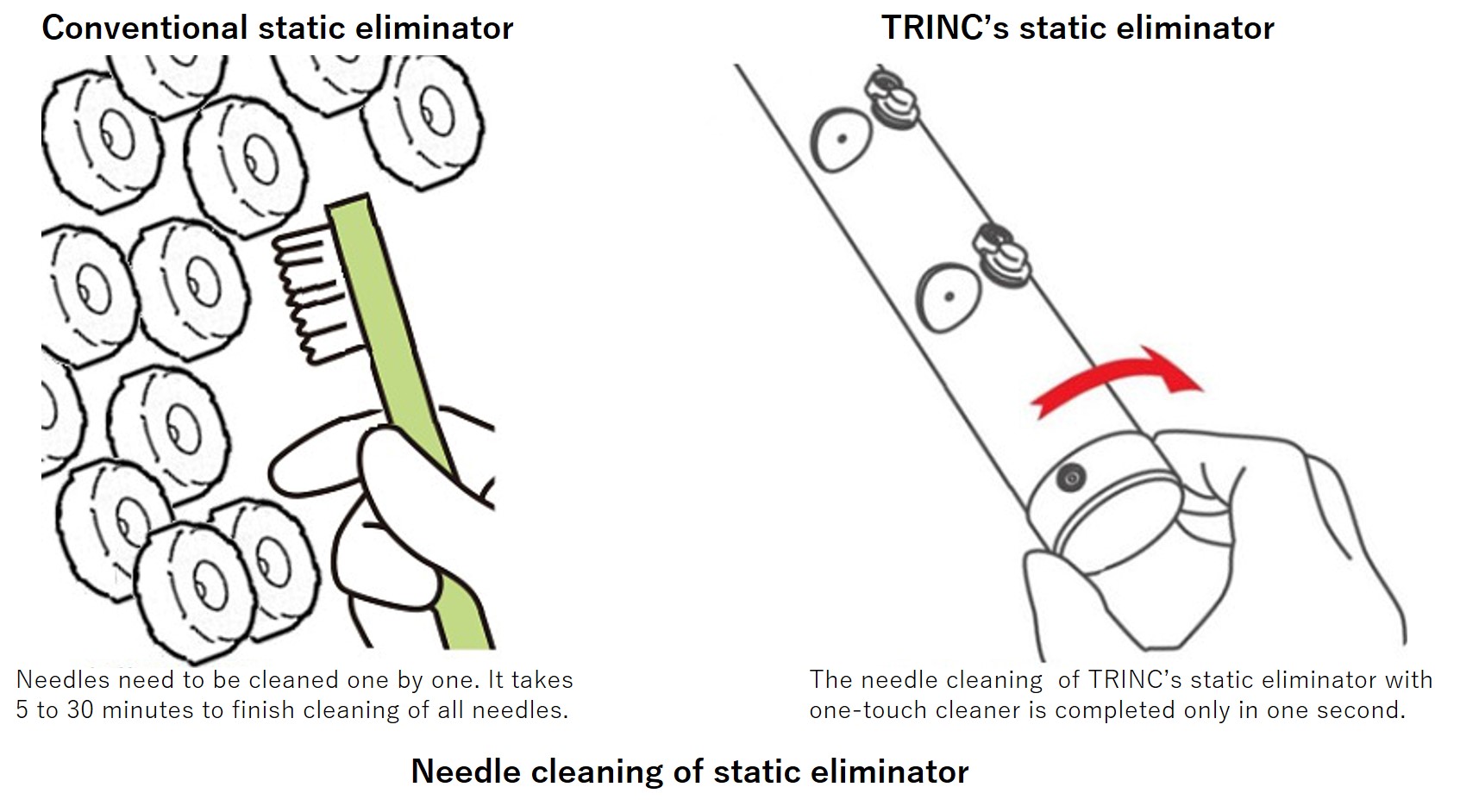

Ease of maintenance

Reports indicate that cleaning the discharge needles of static eliminators can take up to 30 minutes, with maintenance crews being required to clean each needle individually. However, TRINC’s one-touch cleaner method allows for cleaning all the needles in just one second. If an electrical leak occurs, the base of the needle gets burnt, making needle cleaning more challenging and potentially requiring replacement. We recommend the use of static eliminators with a leak-free design structure.

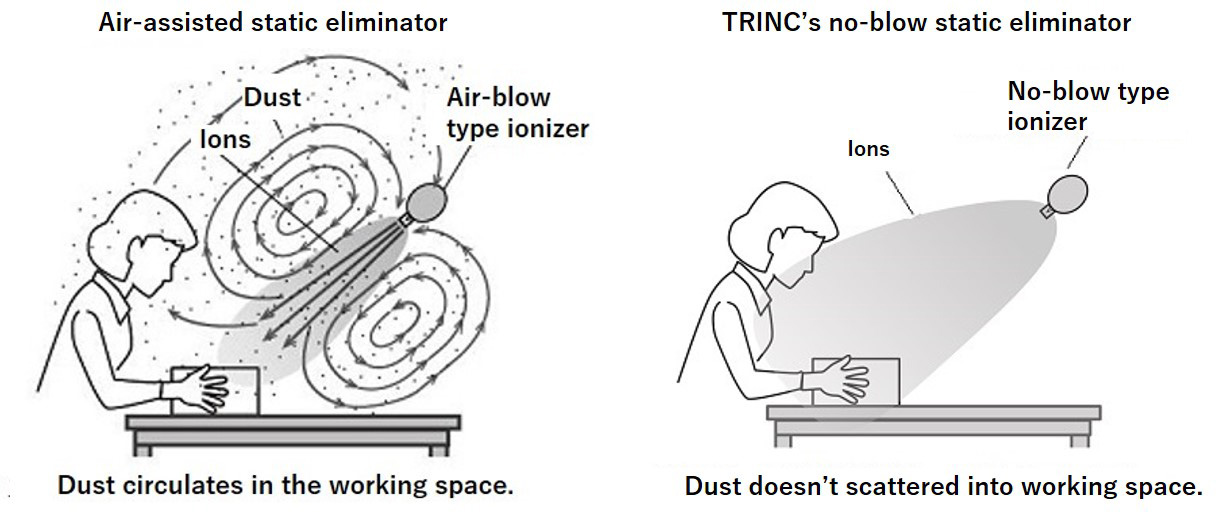

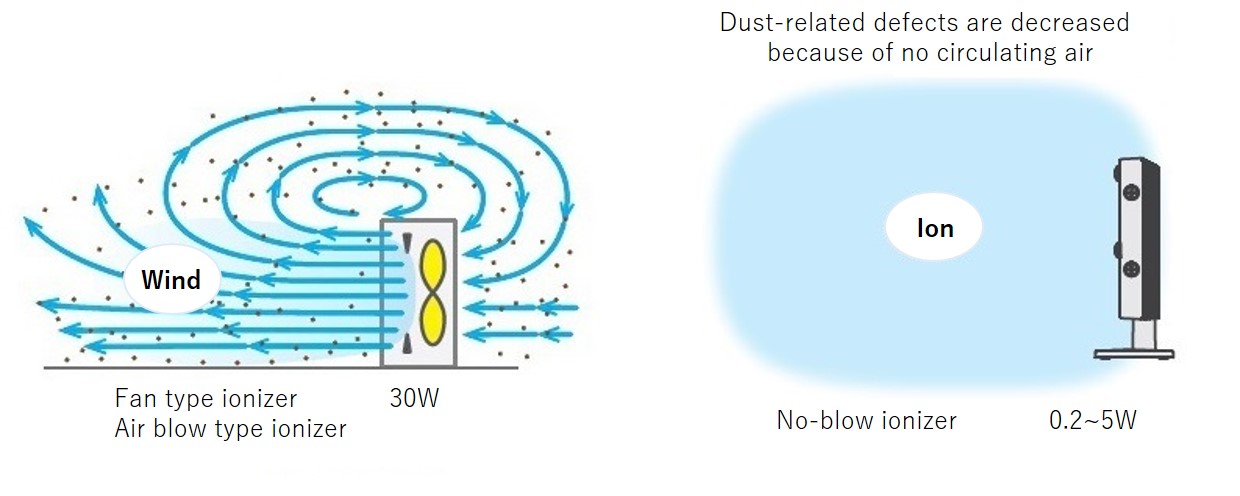

Windless Ionization

We suggest utilizing static eliminators that do not rely on compressed air. High-velocity air can scatter existing dust particles into the working environment. Therefore, using no -blow static eliminators for effective anti-static and anti-dust measures is crucial.

Fan-less Ionizers

Avoid using fan-type ionizers. To prevent contamination and minimize dust scattering, it is essential to use “no-blow” static eliminators. Fan-type ionizers can contribute to dust-related defects.

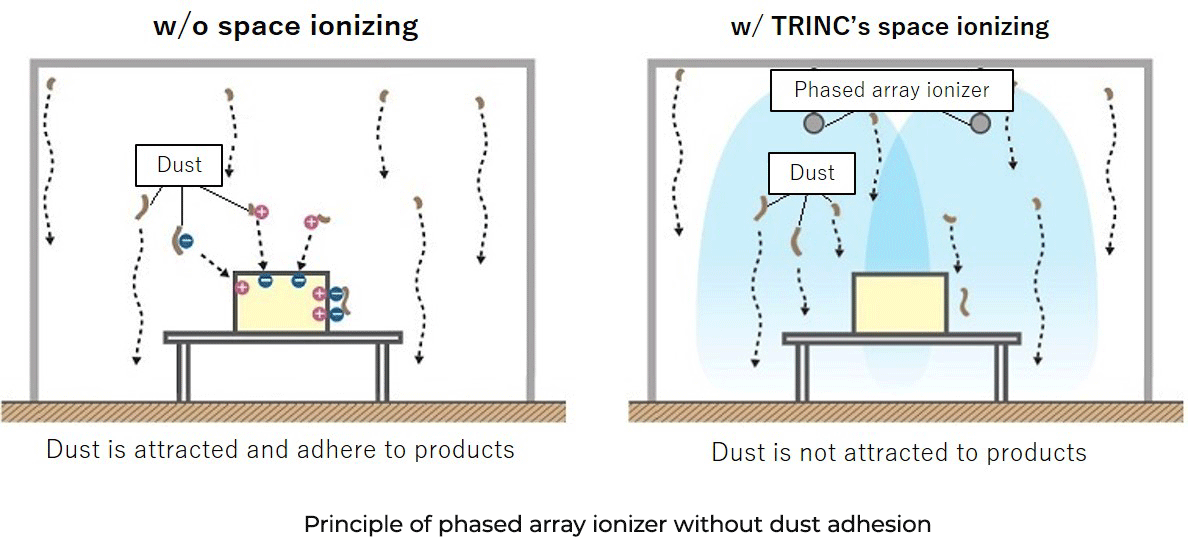

Removing static from objects and dust

To prevent dust’s adhesion to products, removing static electricity from airborne particles is crucial. Utilizing a fan-type static eliminator can also contribute to dust scattering, leading to